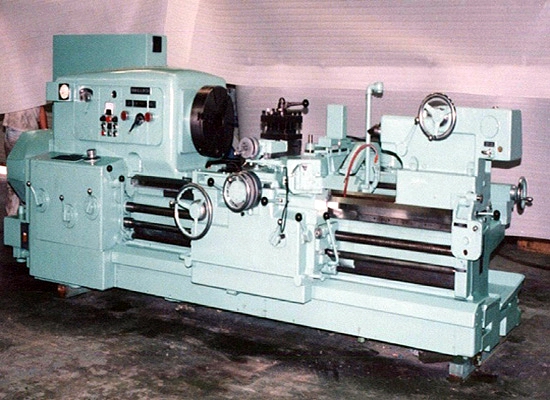

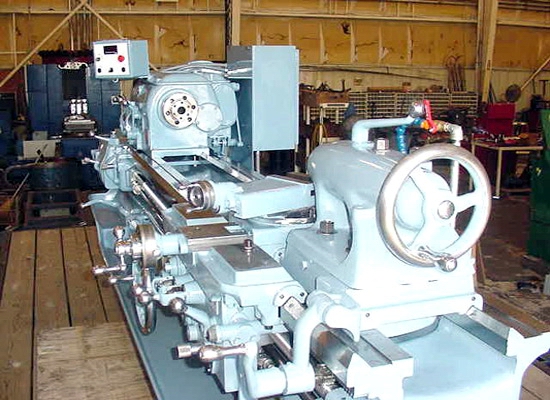

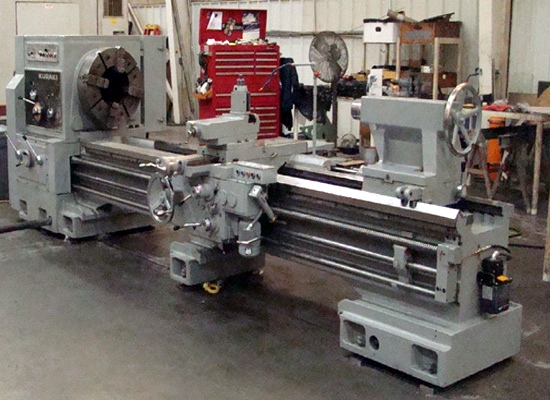

Machine Tool Remanufacturing

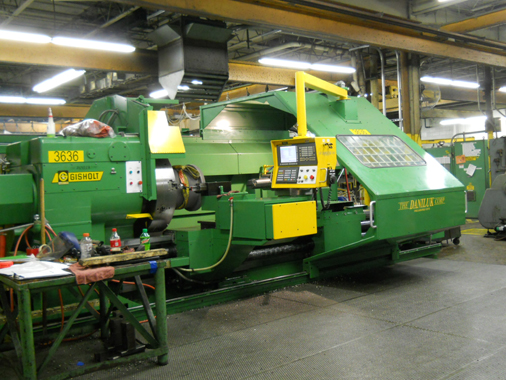

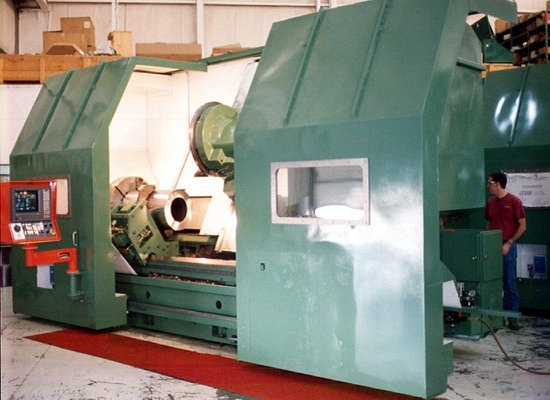

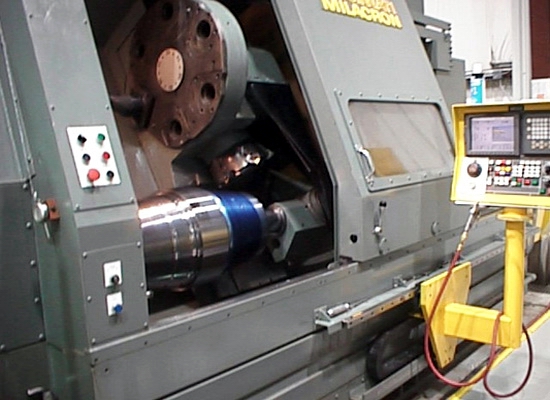

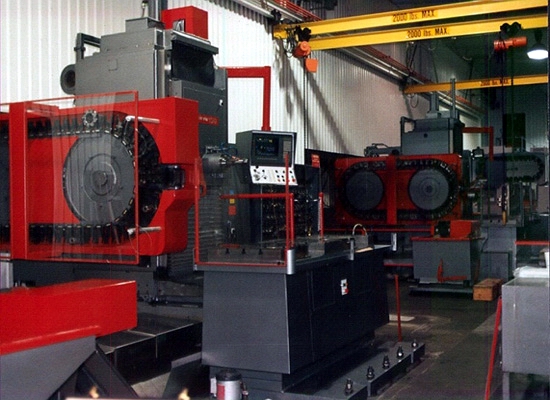

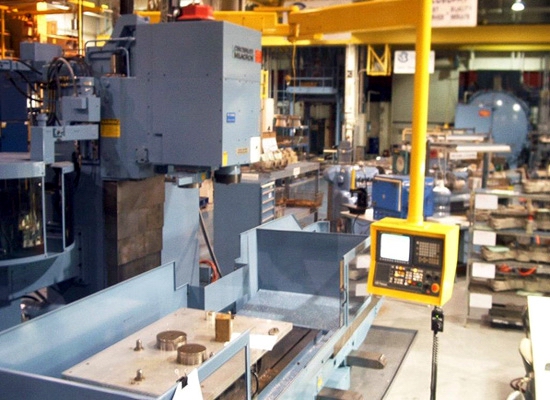

The Daniluk Corporation is the leading rebuilder of large machine tools in the United States. Our in-house engineering, machining, way grinding and highly trained machine rebuilding technicians offer the best machine rebuild program available. Daniluk has an extensive experience in medium to large machine tool rebuilding. One or our specialities is to convert manual machines to full CNC including upgrading the drive system to the latest technology in precision ball screws and servo systems. All remanufacturing processes are controlled in-house at our Oklahoma City facility. Our processes include full re-engineering of the machine tool, by investigating historical problems a machine has had we make engineering upgrades to eliminate these and improve the machine functionality and accuracy. Major focuses include safety, maintainability, ergonomics, energy conservation, increase machine accuracy and dependability. With improved speeds, feeds and machine accuracy and repeatabilty the productivity on equipment increases significantly.

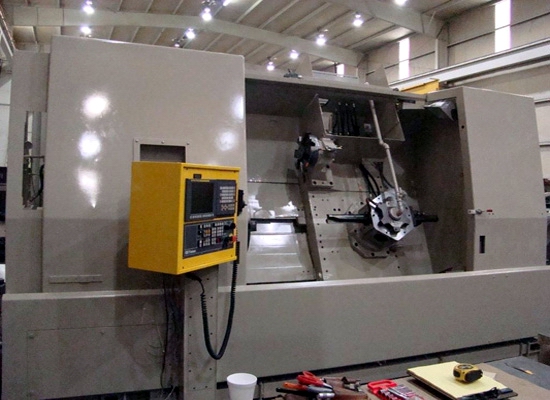

A typical machine remanufacture includes:

Complete disassembly to individual component

Full inspection of all parts to OEM and industrial standards

Sand blast and painting

Precision grinding of ways

Complete rebuild of headstock including replacement of all bearings, seals and clutches

Complete rebuild of tool changers including all new bearings, seals and other wear parts.

Complete rebuild of all axis drive systems including all replacement of ball screws and bearings

Redesign of the ballscrews and drives (new ballscrew bearings and seals)

Installation of Turcite® wear material on all moving surfaces

New way wipers

New CNC controls, axis drives and spindle drive

Complete new electrical system

Complete new hydraulic system

Complete new way lube system

New chip conveyer

Part cut run-off test at Daniluk and customer

Installation assistance

Operator / maintenance training

Full documentation including hard copy and electronic of mechanical / electrical / hydraulic

1 year full coverage warranty on all mechanical and a 2 year full coverage warranty on controls

Danco

Daniluk also builds new vertical boring mills, precision grinders and new specialty machines that are manufactured at

our facility under the trade name DANCO.